Nigel Barber

Senior Design Engineer

MICHELLE OSBORN

Personal assistantDes Wenn

Managing director

Des has been around motorsport for some five decades, firstly during his teenage years as a volunteer St Johns First Aider at Snetterton Circuit. This continued during his early adult life in Short Circuit Oval Racing, Club Rallying taking part in night road and stage events and finally Circuit Racing in Modified Saloons.

DRAWING

Customer’s design requirements be it to drawing, layout or specification will all endure a stringent drawing and verification process the ensures accurate data control.

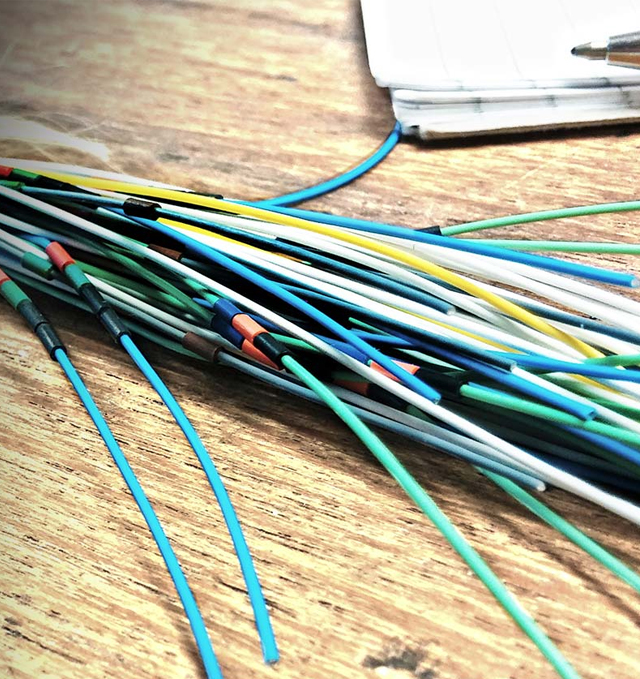

LAYOUT DESIGN

When a customer has an undefined layout, site visits are planned to define requirements and a dummy wiring harness is produced to accurately model the shape needed.

CUSTOMERS SPECIFICATION

When a customer has an undefined layout, site visits are planned to define requirements and a dummy wiring harness is produced to accurately model the shape needed.

QUALITY

The quality of our products are determined by our vision of excellence and high quality military and aerospace materials procured from some of the best industry manufacturers.

All harness/loom products sold by us are hand built in our facility by a very experienced team and subjected to careful inspection and testing in our quality department.

We manufacture to a wide ranging specification to ensure all product meets the high and varied stresses imposed on them in Motorsport including Formula One, LMP Sports-cars, Rally Cars and Super Bikes.

PRODUCTS

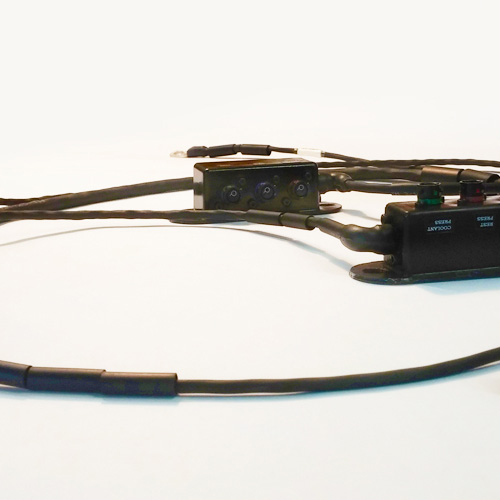

FUEL TANK LOOM OR HARNESS |

The harnesses for fuel cells are normally immersed in the fuel so the connectors need to be hermetically sealed to stop fuel ingress and sleeved with RW175. |

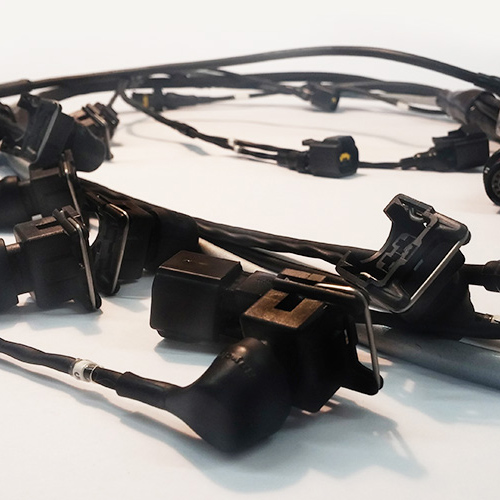

GEARBOX LOOM OR HARNESS |

This harness supplies the rear end of the car so may have rear lighting, sensors and wing functions as well as gearbox controls. It may be a harness only or a combination of harness and a carbon enclosure to link up to all sensors. Normally these are situated in some of the harshest parts of the car, exposed to heat and vibrations so will often be built with RW175 and HFT5000 Sleeving. |

INNER WING / ENGINE COMPARTMENT |

These harnesses are always situated in a very hot environment so will normally be built with a combination of DR25, RW175 and HFT5000 Sleeving and may be part harness and part carbon enclosure. |

FRONT AND REAR LIGHTING LOOM |

Lighting Looms be it front or rear are used for all lighting requirements as demanded by the regulations for the series the car is intending to compete in. The harness is produced to the same standards as all Cyprium Products and may use self-aligning connectors to assist the quick removal or fitting of bodywork. |

ADVERSE WEATHER LIGHT LOOMS |

These are used on all circuit cars and are produced with our standard range of materials common to all our harnesses. |

FRONT CHASSIS LOOM OR HARNESS |

The Front Chassis Loom will vary greatly depending on the type of car it is intended for. On opened wheel series the Front Loom is used for a variety of functions that may include brake, steering and suspension sensors. For LMP and Touring Cars it may also link to the Steering Column Loom providing power and signal for driver and dash panel functions as well as linking to the Font Lighting Loom. This loom will often be fitted with a quick release connector to assist with quick replacement of bodywork sometimes as the result of accident damage. Materials used for construction will vary depending on the application, but will include Type 55a or 55m wire, DR25, RW175 and HFT5000 sleeving. |

ENGINE LOOM OR HARNESS |

This harness varies greatly depending on the series it is to be used in and what the customer requires. Sometimes a very small harness linking the Chassis Loom to a Sensor Box, but it may be a very large loom with injectors, coils and all sensors required to run the engine and directly wired to the ECU. Due to the extreme heat generated from a competition engine a wide variety of sleeving may be used including DR25, RW175 and HFT5000. |

CHASSIS LOOM OR HARNESS |

The Chassis Harness is also known as the Main Harness, Cockpit Harness, Cabin Harness or Driver Compartment. This is normally the largest loom on the car linking power and signal to all other looms, components and driver controls. It may be hidden away between layers of bodywork so will be made as small as possible to fit into the tightest of places. |

DYNO AND BENCH TEST HARNESSES |

Bench Test Looms are sometimes a scaled down version of the loom used on the car, made with Type 55a or 55m wire, but only secured with lacing cord or spiral wrap sleeving so wires can be added or relocated as the design develops. Dyno Looms however will normally be sleeved in DR25 and HFT5000 in a fully sealed system to stop fluid ingress as they are used in what can be a very harsh and messy environment. |

KNOW HOW

Cyprium motorsports is perceived as an engineering solutions provider in the motorsports industry for design manufacture and installation of wiring harnesses or looms and beyond, we appoint small teams that work closely with each customer, delivering the required solution, product to the car and racetrack.

THE WINNING ATTITUDE

We are very proud to have been a part of the team that has worked on the Ford GT 2016 Le Mans 24 hour race. Our engineers at Cyprium have proven to be a critical link in the Ford GT, we have designed, manufactured and installed the complete car that went on to win the class in 2016.

Cypium Motosports works very closely with many world class Formula 1 manufacturers from the UK to Japan and beyond. The insight into a high tech motorsports world has been paramount for the success of Cyprium, the knowledge and expertise is shared and has evolved into cutting edge solutions for our customers.

Cyprium has also been awarded four contracts in Formula E and the supply of complete car sets.

BLOG

CONTACT US

Redgrave Business Centre, Gallows Hill, Redgrave, Diss, IP22 1RZ, UK

+44 (0)1379 897262

+44 (0)1379 897377